Tokyo-based materials company Proterial recently announced a method for shaving more than 20% off the harmful carbon pollution made by processing nickel-based material for lithium-ion batteries. As Nikkei Asia reported in May, Proterial's new process could reduce the overall carbon emissions of building lithium-ion batteries for electric vehicles (EVs) by more than 10% — making these planet-friendly forms of transportation even friendlier.

The batteries are key components of EVs, which are seeing a recent surge in popularity, in part, due to their environmental and cost-saving attributes.

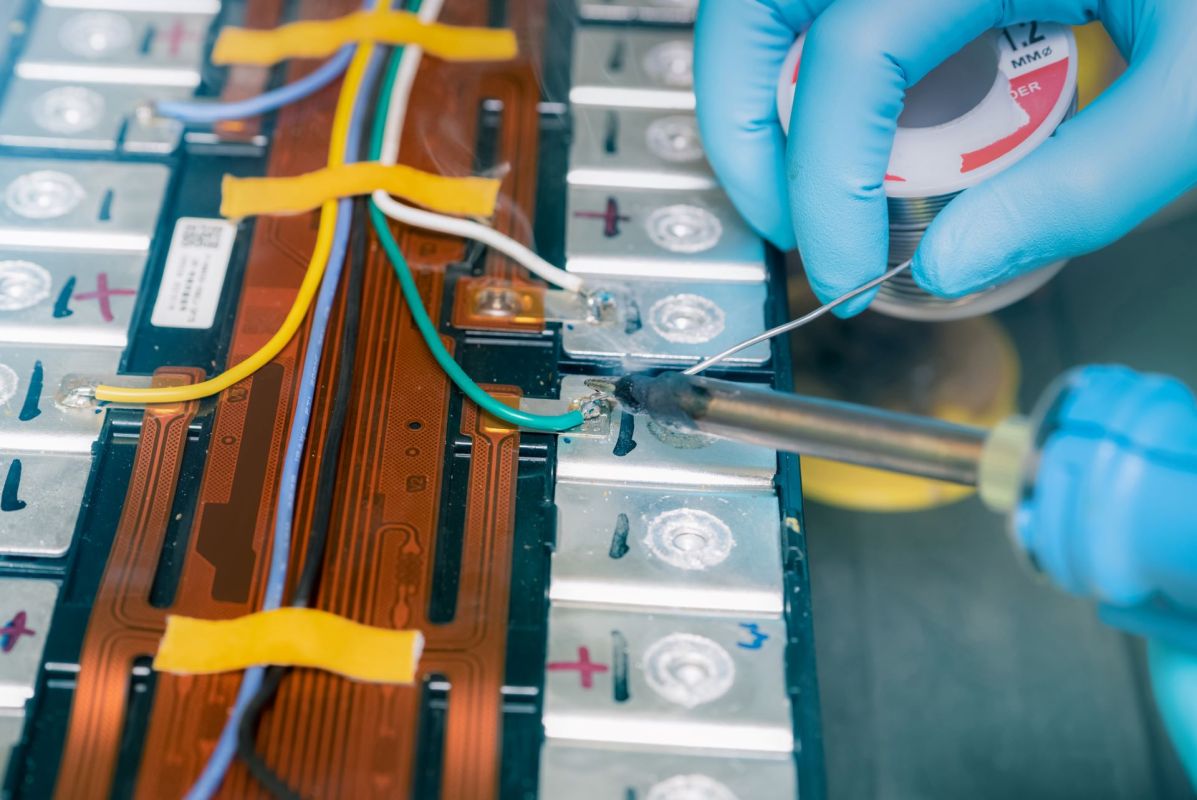

Proterial, known as Hitachi Metals until January, explained in a press release that its newly developed method achieves carbon reductions by avoiding a "previously required" chemical process for making nickel used in cathodes.

Cathodes are a crucial and expensive part of any lithium-ion battery, and producing them accounts for much of the planet-warming gas produced by EV battery manufacturing.

Numerous reports have shown that EVs with these batteries generate less heat-trapping gas over their lifetimes than conventional vehicles, even factoring in manufacturing and the generation of electricity used to run them. This is mostly because EVs do not release the tailpipe pollution of gas-burning vehicles.

That said, there is a great opportunity to reduce the carbon pollution caused by building EVs and especially the carbon-intensive process of building batteries. Proterial's new tech would be a way to reduce the emissions of EV battery manufacturing and EVs overall.

A 10% reduction in pollution from streamlining nickel production could be significant as the accelerating demand for EVs drives a related surge in demand for battery-grade nickel.

Statista reported earlier this year: "The global demand for nickel to be used in electric vehicle batteries only amounted to [about 66,000 tons] in 2018. This number is expected to increase over tenfold by 2025 to some [733,000 tons] worldwide. A shift in the automotive industry towards electrification is driving the rapid growth."

To meet international goals of reducing pollution for a cooler, healthier climate, experts foresee a continuing shift toward renewable solutions that require batteries — and minerals.

The International Energy Agency predicted that "global clean energy transitions will have far-reaching consequences for mineral demand over the next 20 years." And the International Finance Corporation has said that nickel is one of "at least 17 minerals and metals requiring significantly expanded production to meet net zero emissions goals by 2050."

Meanwhile, governments are also beginning to place stricter requirements on EV makers to disclose their manufacturing pollution, as Nikkei Asia reported.

This all makes it even more important for nickel production itself to be a cleaner process.

For now, Proterial's method of nickel production has only been proven using an experimental prototype, per Nikkei Asia. The company hopes to start working with battery makers and predicts that its new technology will be available commercially by 2030.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.