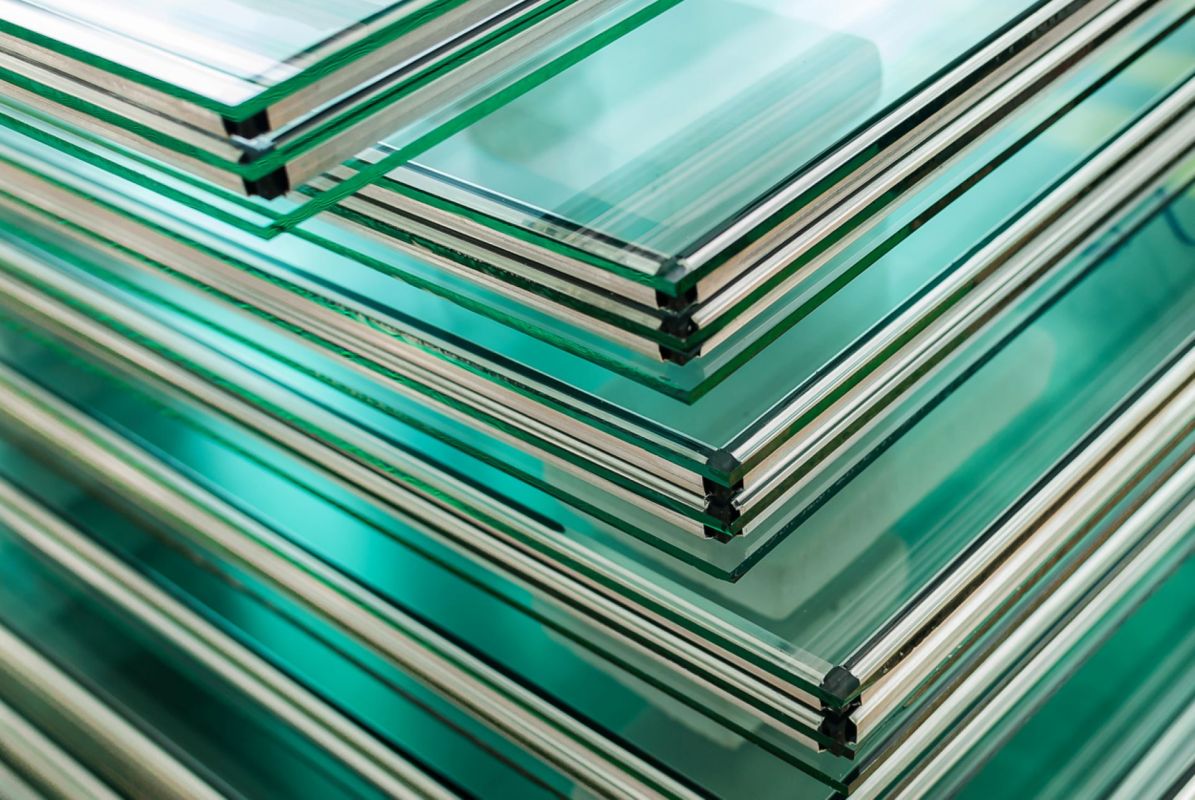

A new form of glass could break open the possibilities for this material — by being much less breakable and far less energy-intensive to make.

Researchers at Penn State University recently filed for a patent on the breakthrough invention, which they've named LionGlass after their school's mascot — the Nittany Lions.

The research team reported that the new glass consumes about 30% less energy when created than conventional glass and promises to release half the carbon pollution that contributes to overheating the planet.

LionGlass is also at least 10 times as resistant to cracking as normal glass, though the limits of its strength aren't yet known, the researchers explained, because their tests couldn't measure them.

"We kept increasing the weight on LionGlass until we reached the maximum load the equipment will allow," Nick Clark, a postdoctoral fellow on the research team, said in a statement. "It simply wouldn't crack."

Even so, the researchers may have cracked the code on heat-trapping gas released from glass production. Although glass manufacturing only accounts for about 0.3% of all heat-trapping carbon releases worldwide, that still amounts to nearly 95 million tons each year, according to a paper in the Journal of Industrial Ecology.

That's equivalent to the heat-trapping pollution of more than 19 million gas-powered vehicles driving for a year, per the Environmental Protection Agency.

The traditional way to make glass is to apply extreme heat to a mix of three substances: quartz sand, soda ash, and limestone. Traditional glass can have a melting temperature of over 2,700 degrees Fahrenheit, per Glass International. Heating the material is responsible for most of the process's energy use and pollution, though chemical reactions involved also release pollution.

LionGlass has a different batch of input materials, with a melting temperature of up to 720 degrees Fahrenheit lower. This accounts for cutting energy consumption by nearly a third. The raw materials also contain less carbon.

"Our goal is to make glass manufacturing sustainable for the long term," Professor John Mauro, the project's lead researcher, said in a Penn State release.

Due to the strength of LionGlass, Mauro also hopes that products that use it can be thinner and lighter, leading to further benefits.

"If we have a lighter-weight product, that is even better for the environment, because we use less raw materials and need less energy to produce it," he said, adding that there could be still more savings considering the products are lighter to transport.

The researchers are still assessing the potential of LionGlass.

As BBC News noted, "Few details about LionGlass are available, as the research has not been published in a peer-reviewed journal yet and the team have only recently filed a patent application."

There may be limitations, explained the outlet, such as not being usable for smartphone screens because it can't handle high temperatures during production.

Still, there are plenty of other possible applications, and the team seeks a patent for a whole "family of glasses" in different compositions that could help the world in various ways.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.