Shoemaker Hilos is putting its foot down when it comes to waste in the footwear industry.

The company's founders are leveraging advances in 3D technology to help make shoes they say are better for the environment.

"We blend digital design and artisan craftsmanship to deliver personalized products made locally and sustainably," Elias Stahl, co-founder and CEO of the Portland, Oregon, company, said in a video on the Hilos website.

It began when the startup's leaders, which include former Nike execs Eric Sprunk and Greg Bui, joined forces about three years ago with the goal of tackling overproduction and waste in the industry, according to GreenBiz.

As Stahl points out in the Hilos video, about 24 billion pairs of shoes are made around the world each year, using about 48 trillion gallons of fresh water (up to 50 trillion by some calculations).

"Of this staggering number, one out of every five goes straight to the landfill," he said in the video.

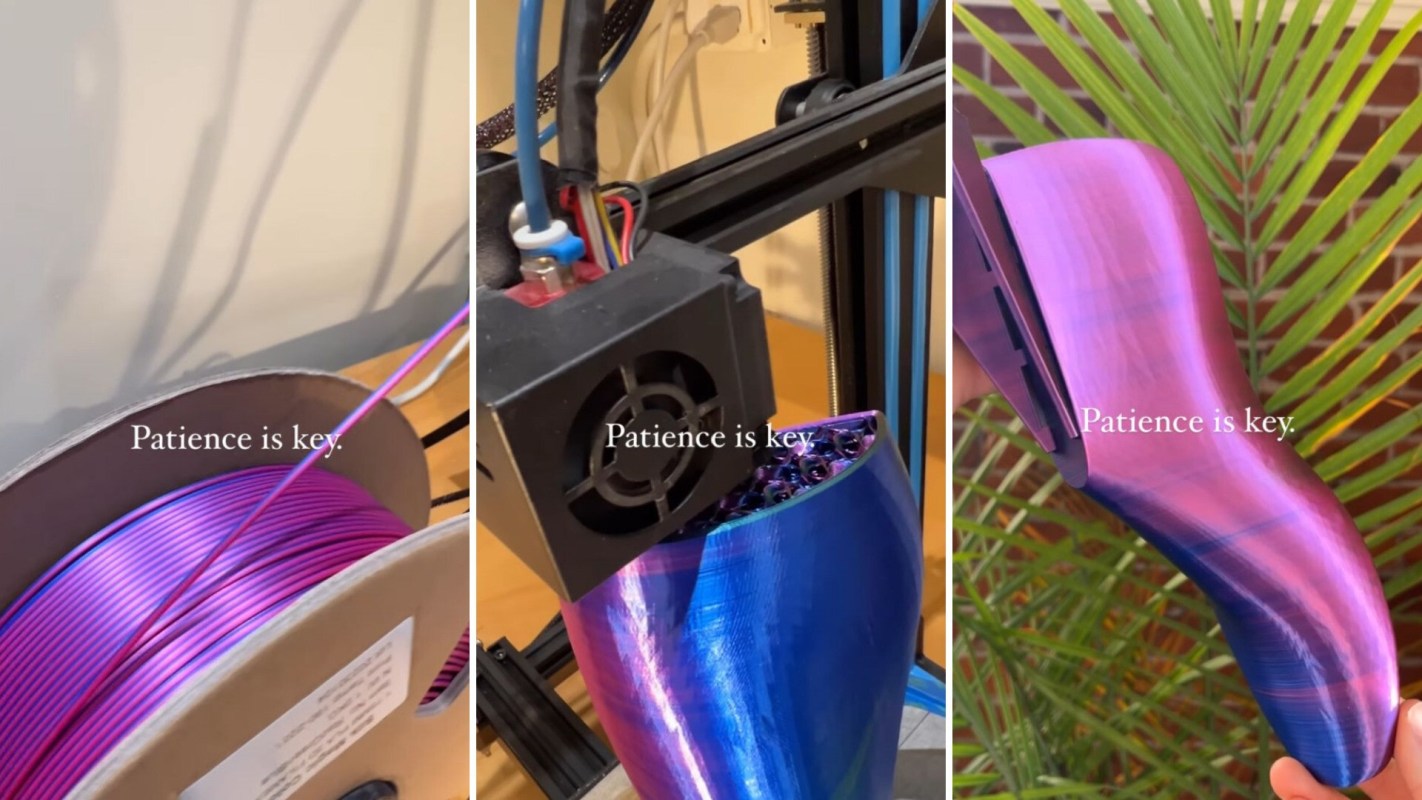

Hilos uses a unique 3D printing process to make the platform of the shoe, which includes the sole, heel, and parts between. The technique greatly reduces the amount of glue needed to assemble the footwear, GreenBiz reports.

The upper part of the shoes is attached with cables, a process GreenBiz said is unique. It also drops the pieces needed for each pair from 65 to five and the number of steps to assemble them from 360 to 12. A shoe can be put together in about an hour, instead of the typical four hours for most shoes, according to GreenBiz.

Hilos are made-to-order, another personalized perk that reduces waste. Once bought, the goal is to have the shoes ready to ship in 72 hours, Hilos claims.

GreenBiz reported that the 3D printer uses a thermoplastic polyurethane powder, often called TPU. And the 3D process itself doesn't result in cleaner air, according to a Yale study. "Only when a complete assembly of the shoe is taken into account does the overall carbon efficiency of 3D printing stand out," GreenBiz reported, quoting the study.

The study showed the entire Hilos process results in a 48% reduction in the release of planet-warming carbon and uses 99% less water compared to the ways most other shoes are made.

Stahl also told GreenBiz that Hilos is working toward using recycled or bio-based materials in place of TPUs. The shoes are made to be easily broken apart and recycled when they wear out, as well.

"How we make things matters," Stahl said in his video.

One shoe example is the Emmett Whiskey mule, billed as comfortable enough for wearing around the house but stylish enough to carry you on your day uptown. It's made with a vegetable-tanned leather upper as part of a collaboration between Hilos and shoemaker Helm. The Emmet Whiskey listed for $225 before the available stock sold out, but the company is just getting started.

So far, though, the shoes had been getting good reviews.

"I walked 13 miles in these shoes. I had zero complaints," one customer said in the Hilos video.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.