The power of oranges may soon transcend food and drink.

That's because experts in the U.S. Energy Department's Oak Ridge National Laboratory are using the fruit's acid to help make a solution that can recycle crucial and expensive lithium-ion battery parts.

If the team from Tennessee can perfect the mix, it could result in lower power pack costs, and ultimately, electric vehicle costs.

"We are glad this recycling process developed by our scientists can pave the way for greater recovery of battery critical materials," Ilias Belharouak, head of the lab's electrification section, said in an Oak Ridge summary.

The science improves on current recycling methods, which mostly include hazardous chemicals and potent acids, according to the lab. Projects at Germany's Tozero and other research efforts at Oak Ridge are among the breakthroughs for more planet-friendly reuse processes.

Otherwise, the precious battery materials are often burnt or mulched and dissolved with chemicals, according to the experts. Batteries will continue to become more prevalent as EVs grow in popularity, but Princeton estimates that only 5% of power packs are recycled in the United States.

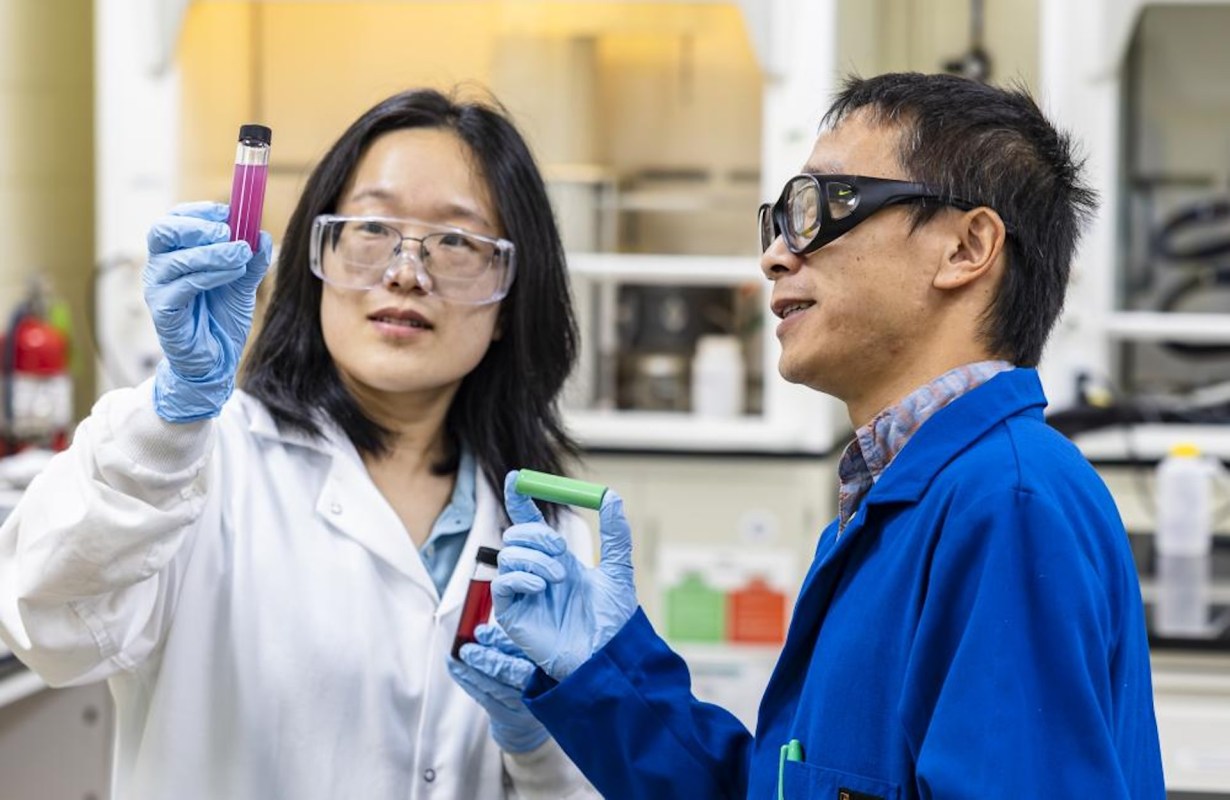

Oak Ridge's latest method could help increase that percentage. It works by soaking batteries in a mixture of natural acids from oranges, which are dissolved in ethylene glycol, an ingredient in common products like makeup and paint, per the researchers. The solution was particularly good at separating mostly all of the costly cobalt and lithium from the cathode in about an hour.

"Because the cathode contains the critical materials, it is the most expensive part of any battery, contributing more than 30% of the cost," Oak Ridge researcher Yaocai Bai said in the summary. J.D. Power estimates that EV batteries can cost between $4,000 and $20,000, for reference.

The Oak Ridge testing marked the first time a single solution could leach and recover the metals.

"It was exciting to find that the cobalt would precipitate and settle out without further interference. We were not expecting that," lead researcher Lu Yu said in the lab report.

Faster, cleaner battery recycling methods could propel an already growing industry. Statista reports that worldwide lithium-ion recycling was estimated at $9.4 billion last year. The data collector forecasts it to be greater than $18 billion by 2031.

But the planet could be the big winner here. Widespread recycling will reduce the need for invasive mining required to collect the hard-to-gather battery metals, as well as lessen demand for them from foreign markets. It all adds up to lower-cost EVs, easing the transformation of our transportation system to cleaner vehicles.

"Our approach could reduce the cost of batteries over time," Bai said in the lab report.

What's more, EV drivers save about $1,500 on gas and maintenance, as well as prevent 10,000 pounds of air pollution from being spewed from an exhaust each year. Dropping the pollution burden can in turn improve human health, as the dirty air is being increasingly linked to cancer, dementia, and heart disease.

So, it seems that better health for the body and planet can be aided by orange juice.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.